FSOFT Oil and Gas

FSOFT Oil and Gas SME knowledge sharing pages. Information and photos displayed here are sourced from the internet, and maybe subjected to copyright by their respective site's owner.

Drilling

A well is constructed from several different sections. In each section, the following main operations will typically take place:

- A hole is drilled into the earth.

- A casing string is run into the borehole to maintain stability.

- The casing is cemented into place.

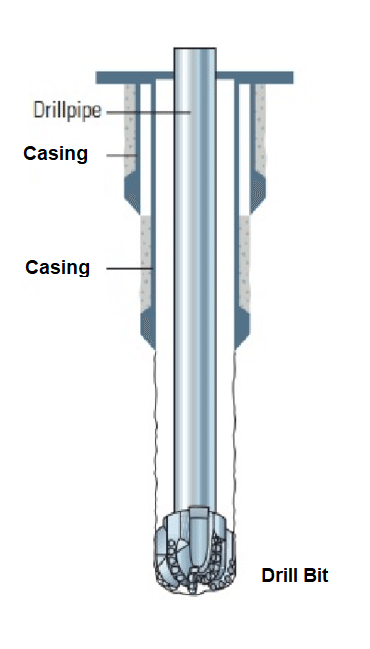

1. Hole Drilling

A hole is drilled with a drill string and a drill bit attached at its end. The OD of the drill bit determines the hole size.

During drilling operation, drilling fluid is pumped continuously into the hole to cool down downhole equipment and to bring cuttings to surface for disposal.

2. Casing Running

Casing with sufficient strength is run into the drilled borehole to support the well. The followings are typical casing types in a well (from top to bottom):

- Conductor (shallowest setting casing string).

- Surface Casing.

- Intermediate Casing (multiple sections can have this type of casing).

- Production Casing (deepest setting casing string, right at or just above reservoir interval / perforation zone).

A casing that is hung inside another casing is called a liner (the top of the liner does not extend to surface or wellhead).

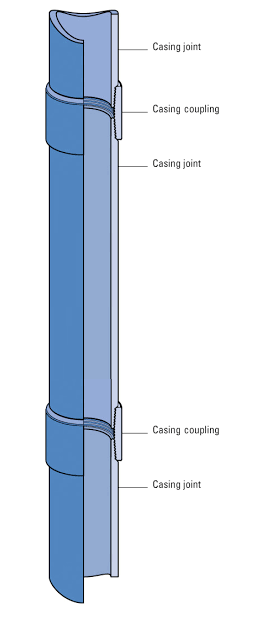

A casing string is constructed by connecting multiple casing joints together. The joints are connected at the couplings (connections) which have slightly larger OD than the casing.

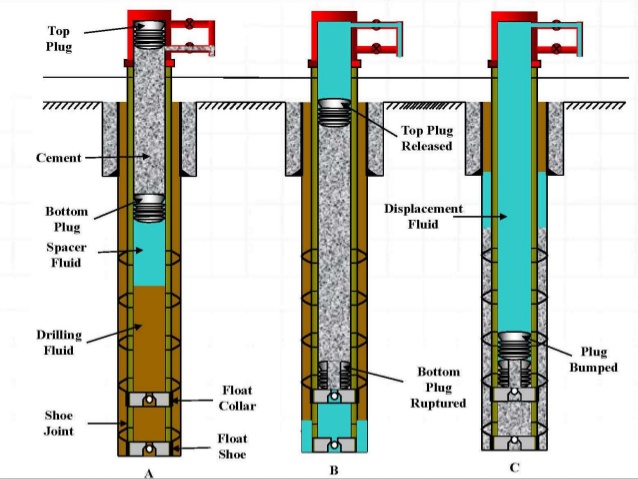

3. Casing Cementing

Cement is used to hold casing in place and prevent fluid migration between layers of rocks.

Cement slurry is pumped through the inside of casing and exits to the annulus through the casing shoe. To prevent contamination, a bottom plug is dropped inside the casing before cement is pumped, and a top plug is dropped on top of the slurry column. Therefore, the cement column is always isolated between the 2 plugs inside the casing.

A spacer is usually pumped before the cement slurry to clean out the inside of the casing and the annulus, avoiding contamination and improving cement bond.